A Kúpos csavaros hordó egy speciális alkatrész, amelyet széles körben használnak a műanyag extrudálás és fröccsöntő iparban. A hagyományos hengeres hordóktól eltérően a kúpos csavaros hordók elvékonyodó kialakításúak, amelyek átmérője fokozatosan csökken a betáplálási zónától a nyomóvégig. Ez az egyedülálló szerkezet javítja az anyagkezelést, az olvasztási hatékonyságot és az általános folyamatstabilitást.

A kúpos csavaros hordókat különösen nagyra értékelik, mert képesek különféle anyagok kezelésére, beleértve a hőre lágyuló műanyagokat, kompozitokat és újrahasznosított műanyagokat, így sokoldalú választás a modern gyártási folyamatokban.

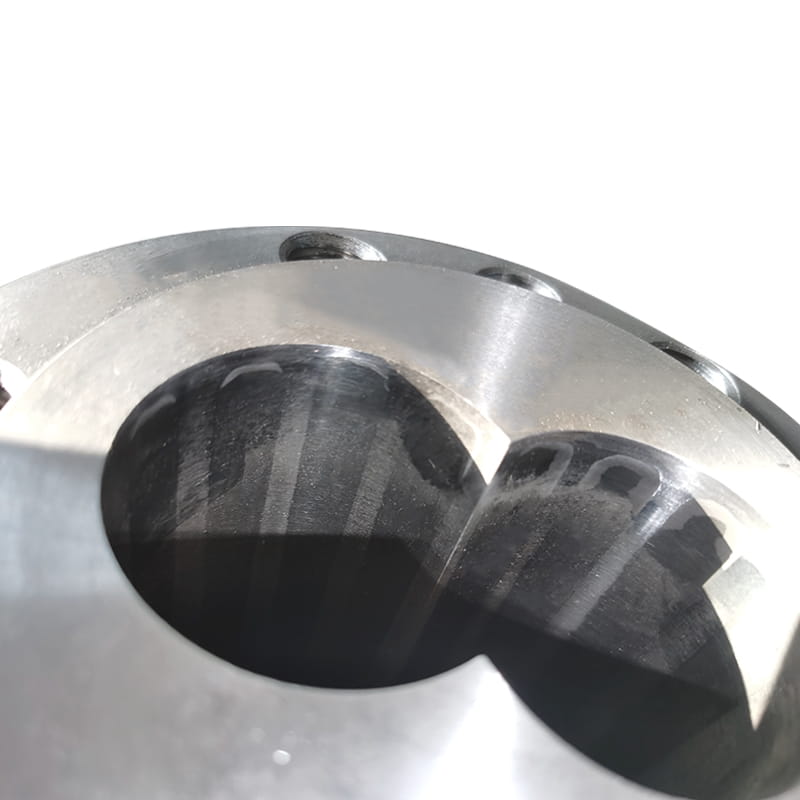

Kúpos csavaros hordók felépítése és kialakítása

A Kúpos csavaros hordó több kulcsfontosságú részből áll, amelyek együttesen javítják az anyagfeldolgozást:

- Táplálkozási zóna: A wide opening at the start of the barrel ensures smooth material intake and reduces the risk of clogging.

- Tömörítési zóna: A barrel gradually narrows, compressing the material, which increases density and facilitates uniform melting.

- Mérési zóna: A final section ensures that the melted material is evenly pushed toward the die or mold, maintaining consistent output.

A screw itself often has a variable pitch and depth to match the tapering barrel, further optimizing melting and mixing performance.

Hogyan működik a kúpos csavaros hordó

A operational principle of a Kúpos csavaros hordó elvékonyodó geometriáján alapul. Ahogy a nyersanyag belép a széles adagolószakaszba, a csavar finoman előremozgatja, miközben a csökkenő átmérő összenyomja az anyagot. Ez a tömörítés hőt és mechanikai energiát termel, elősegítve a homogén olvadást. Mire az anyag eléri a keskenyebb kisülési szakaszt, egyenletes állagot és hőmérsékletet ért el, készen áll az extrudálásra vagy fröccsöntésre.

Ennek a működési elvnek a fő előnyei a következők:

- Csökkentett anyag tartózkodási idő, megelőzve a hődegradációt.

- Fokozott olvasztási hatékonyság a nagy viszkozitású anyagoknál.

- Az adalékanyagok vagy töltőanyagok jobb keverése és diszpergálása.

- Alacsonyabb energiafogyasztás a hagyományos hengeres hordókhoz képest.

Összehasonlítás a hengeres csavaros hordókkal

Míg a hengeres csavaros hordókat széles körben használják szabványos extrudálási és fröccsöntési alkalmazásokban, Kúpos csavaros hordós bizonyos forgatókönyvekben határozott előnyöket kínálnak. Itt egy részletes összehasonlítás:

| Funkció | Hengeres csavaros hordó | Kúpos csavaros hordó |

|---|---|---|

| Anyagkezelés | Alacsony és közepes viszkozitású anyagokhoz jó | Kiválóan alkalmas nagy viszkozitású, újrahasznosított vagy kompozit anyagokhoz |

| Olvadási hatékonyság | Normál olvasztás potenciális forró pontokkal | A fokozatos összenyomás egyenletes olvadást biztosít |

| Keverési képesség | Mérsékelt keverés | Az adalékanyagok és töltőanyagok kiváló diszperziója |

| Energiafogyasztás | Kemény anyagokhoz magasabb | Alacsonyabb a hatékony tömörítés és olvasztás miatt |

| Költség | Alacsonyabb kezdeti befektetés | Magasabb, de az igényes alkalmazások teljesítménye indokolja |

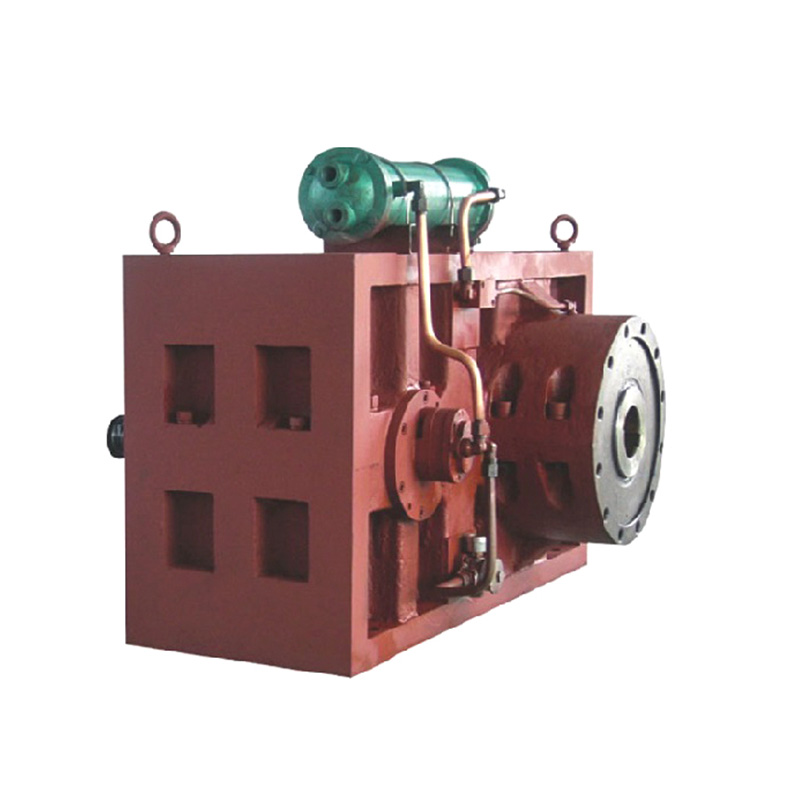

Kúpos csavaros hordók alkalmazásai

A versatility of the Kúpos csavaros hordó alkalmassá teszi különféle iparágakban és folyamatokban:

- Műanyag extrudálás: Hatékonyan kezeli a nagy viszkozitású polimereket és kompozit anyagokat.

- Fröccsöntés: Egyenletes olvadást biztosít, és csökkenti a fröccsöntött alkatrészek hibáit.

- Újrahasznosító ipar: Ideális változó szemcseméretű újrahasznosított műanyagok újrafeldolgozására.

- Összeállítás: Elősegíti az adalékanyagok, töltőanyagok és színezékek keverését az alappolimerekbe.

A kúpos csavaros hordó használatának előnyei

Megvalósítása a Kúpos csavaros hordó a gyártósorokon számos előnnyel jár:

- Jobb olvadékhomogenitás és termékminőség.

- Csökkentett energiafogyasztás és üzemeltetési költségek.

- Az újrahasznosított vagy kompozit anyagok továbbfejlesztett kezelése.

- Minimálisra csökkenti az anyagromlás kockázatát a rövidebb tartózkodási idő miatt.

- Jobb alkalmazkodóképesség a polimer viszkozitások széles skálájához.

Karbantartási és üzemeltetési tippek

Az élettartam és a teljesítmény maximalizálása érdekében a Kúpos csavaros hordó , a megfelelő karbantartás elengedhetetlen:

- Rendszeresen ellenőrizze a csavarokat és a hengereket kopás és elhasználódás szempontjából.

- Tartsa tisztán a hordót, hogy megakadályozza az anyag felhalmozódását és a szennyeződést.

- Figyelje a hőmérséklet- és nyomásbeállításokat, hogy elkerülje a túlmelegedést vagy a túlzott összenyomást.

- Az állandó minőség megőrzése érdekében azonnal cserélje ki a kopott csavarokat vagy hordórészeket.

Gyakran Ismételt Kérdések (GYIK)

1. Egy kúpos csavaros hordó képes kezelni az újrahasznosított műanyagokat?

Igen, a kúpos kialakítás a hatékony tömörítési és keverési zónáknak köszönhetően kiválóan alkalmas az újrahasznosított műanyagok feldolgozására, még a különböző szemcseméretű vagy szennyeződésűek esetében is.

2. A kúpos csavaros hordó alkalmas minden típusú polimerhez?

Bár rendkívül sokoldalú, különösen előnyös a nagy viszkozitású polimerek, kompozitok és alapos keverést igénylő anyagok esetében. Alacsony viszkozitású szabványos műanyagokhoz elegendő lehet a hengeres hordó.

3. Hogyan javítja az energiahatékonyságot?

A gradual compression reduces mechanical and thermal losses, requiring less energy to achieve uniform melting compared to traditional cylindrical barrels.

4. Vannak-e hátrányai?

A main consideration is the higher initial cost and complexity. However, the improved processing efficiency and product quality often justify the investment in demanding applications.

5. A meglévő extrudáló gépek utólag felszerelhetők kúpos csavaros hordóval?

Igen, a meghajtórendszer és a hordórögzítés megfelelő tervezésével és beállításával sok gép fejleszthető úgy, hogy kúpos csavaros hengert építsen be, ami fokozott teljesítményt biztosít.

Következtetés

A Kúpos csavaros hordó jelentős előrelépést jelent az extrudálás és fröccsöntés technológia terén. A tömörítés, az olvasztás és a keverés optimalizálásával javítja az anyagkezelést, csökkenti az energiafogyasztást és javítja a termék minőségét. Legyen szó újrahasznosított műanyagok, nagy viszkozitású polimerek vagy kompozit anyagok feldolgozásáról, ez az innovatív hordókialakítás megbízható megoldást kínál a modern gyártási kihívásokra.

A hagyományos hengeres hordókkal összehasonlítva a kúpos kialakítás egyértelműen kiemelkedik sokoldalúságában, hatékonyságában és alkalmazkodóképességében, így elengedhetetlen eszköze a kiváló minőségű termelést és működési hatékonyságot célzó iparágaknak.